The mobile manipulator robot TIAGo in Project RobMoSys

PAL Robotics has been one of the consortium partners since project RobMoSys started in early 2017, alongside the Eclipse Foundation, Comau, Siemens, TUM (Technical University of Munich), KU Leuven (Katholieke Universiteit), THU (Ulm University of Applied Sciences) and the CEA (The French Alternative Energies and Atomic Energy Commission).

RobMoSys aims to coordinate the whole community’s best efforts to realise a step-change towards a European ecosystem for open and sustainable industry-grade software development for robotics.

To accomplish this approach, RobMoSys has two General Principles:

- Separation of Roles and Concerns enables focussing on development workflow and expertise. Roles (robotics experts, domain experts, component suppliers, system builders, as well as installation, deployment and operation specialists) work autonomously.

- Composability is the ability to break robotics systems into smaller components. This facilitates the predictability of global properties like timing and safety by still preserving component properties.

The models follow a general composition-oriented approach where systems can be constructed out of reusable software components (building blocks) with explicated properties. Therefore, it is possible to exchange software components from different systems and operational contexts while saving software development costs.

TIAGo robot by PAL Robotics is used as a platform to show the model driven methodology in RobMoSys that fosters interoperability through composability and configurability principles. In particular, TIAGo shows the use of this methodology in a healthcare use case (pilot).

With the project now approaching its official end date, we managed to talk with Project Coordinator, Dr. Huascar Espinoza as well as with Dr. Luz Martinez of the Technical University of Munich, to find out more about the original project goals, the contributions of consortium partners, the benefits of the RobMoSys approach and the desired impact on the future of European robotics.

1. Can you tell us more about the background of RobMoSys and how the project originally started?

“The aim of the RobMoSys project is to create software modules for robotics that can be easily put together and easily reused; modules that are predictable, including guidance on what you have to change within these modules to achieve different goals in robotics.

With the RobMoSys approach, we are not only thinking about how to programme robots, we are also concerned with the certification of robots – and for this analysis of software is needed.

In order to work on predictability, we don’t just look at the code but also need to create proper abstractions or models to perform other maths analysis or simulation activities. Here is where model-based approaches, like the one underlying RobMoSys, play a unique and relevant role.

RobMoSys defines modelling design constructs that are specific to the robotics domain (from low-level concepts such as communication patterns used in robotics middleware to high-level concepts such as mission, task, skill, and world models). At present, there is no modelling language that has such a rich set of features specific to robotics that are, nevertheless, generic enough to be applicable to different domains (healthcare robotics, industrial robots, service robots, etc).

To foster the use of models for designing robotics software, graphical views prevail the understanding of the system architecture to perform different kinds of analyses. We use graphical models everywhere to assess the properties that need to be guaranteed for robot certification but also to have a separation of roles within the tools for enabling agile value chains when engineering complex robotics systems.

Another aspect here is interoperability. Some robots use ROS – some others use other software platforms ranging from specialized coding facilities to sophisticated simulation environments. Having standardised the way roboticists design robotic software is essential to be able to communicate with other open standards. RobMoSys enables robot integrators to use, into their proprietary environments, modules that were developed in external environments. This is done by means of bridging facilities that adapt a platform-independent model to a model for a specific target platform. For instance, Papyrus4Robotics – a RobMoSys-compliant toolset, currently provides such bridges for ROS2.

In summary – many technologies exist to develop software in robotics, but there is a lack of consistency and high-quality standards, and we don’t have common patterns to develop these systems. In order to provide this – we created RobMoSys structures – basic building blocks. With these it’s possible to programme the robot, create robot skills, then make low level concepts, and determine how modules will communicate, etc. We also provide tools to instrumentalise this – tools to improve the experience for engineers.”

“Creating software modules for robotics that can be easily put together and easily reused… Many technologies exist to develop software in robotics, but there is a lack of consistency and high-quality standards… We created RobMoSys structures – basic building blocks… We also provide tools to instrumentalise this – tools to improve the experience for engineers.”

2. How have the project partners in the RobMoSys consortium worked together to contribute to the project?

“The project core consortium consists of nine partners funded by the H2020 programme of the European Commission. RobMoSys is a “cascade-funding” project, so that it is able to publish open calls for third-party organisations to contribute to what we are doing. With this baseline we asked the robotics community to propose ideas for the project. For this process, we have had two main open calls and funded more than 30 ideas. These ideas took the form of Integrated Technical Projects (ITPs), which are being executed, and some of which have finished, to improve the RobMoSys software ecosystem and tools with the goal of creating a strong community. Different members of the community bring different strengths – for example some are experts on safety, and some are experts on benchmarking or specific platforms and standards such as ROS or OPC UA.

Each ITP has a coach from the RobMoSys core consortium, who provides guidance and helps them stay on the right path. This is a distinctive characteristic of RobMoSys, as it has established a strong collaboration with ITPs by means of continuous support and supervision. The work done by external partners is fully integrated into RobMoSys through the coaches.

Different project partners make different kinds of contributions to RobMoSys. For example, some partners contribute tools, and others contribute case studies (including the application of ideas) or the improvement of existing case studies, such as for example the one developed by PAL Robotics.

The fast adoption projects for RobMoSys last for six months and mainly SMEs take part, they receive funding and they benchmark the RobMoSys technology. RobMoSys also offers tutorials at full day events and at conferences, aimed at the robotics community and modelling community.”

3. Which goals has RobMoSys reached in robotics and which other goals in relation to the project have still to be achieved?

“In the project so far, three goals we would like to highlight in particular that we have achieved are:

- Very good documentation

- Developed Papyrus4Robotics and SmartMDSD tools (these have been developed according to the RobMoSys approach. These are basic tools, and there are sub tools attached to these tools. These tools are used to build pilots.)

- We have also done successful pilots on systems at TUM, THUlm, Siemens, PAL Robotics, Comau and CEA.

The key here is for systems and tools to be reusable and reliable. All RobMoSys tools are open source, including SmartMDSD. There are two tool sets, and they are complementary.

At THU (ULM) – the team worked on the SmartMDSD toolset, and even decided to create a start-up from this, which is soon to be announced!

With the goals we have still to achieve – we would like to develop more tools, and communicate to users that it’s easy to use certification to set a standard.

Our software tools have helped organisations to comply with standards, and to comply with robotics at operational level. For example, with a robot being used in a factory, it’s necessary to show that the robot won’t cause harm, so we need certification to demonstrate this.

We help with certification by doing risk assessment of software inside robots, by doing analysis for testing or simulation. We are building this but we don’t have a complete set of tools to achieve this yet.”

“We developed Papyrus4Robotics and SmartMDSD tools.Successful pilots on systems and with the goals we have still to achieve – we would like to develop more tools, and communicate to users that it’s easy to use certification to set a standard.”

4. How will the RobMoSys approach help robotics companies?

The RobMoSys approach is aimed at:

- System integrators

- Component suppliers

- End users

- Companies that supply tech software to robotics manufacturers and these use robots manufacturers themselves

Examples of use include using the tools to design the structure of software, and using the information to do analysis of components since they have that component diversion in a standard format.

Robot manufacturers can use this information to build complete robots and certify robots. It’s a matter of facilitating the integration of components into bigger manufacturing systems.”

From a commercial perspective, the main incentives of the RobMoSys approach are:

- reduction of development time, resulting reduced costs and shorter time to market

- systems should become more easily reusable and, as a consequence, should:

- Enable larger production volumes of components and systems (using flexible production units)

- Base components could be commoditised

- Systems will become certifiable

- Safety of systems will be predictable

- Easier reconfigurable systems will allow for mass customization of products

- Better comparability of systems and components will be enabled through appropriate metrics (benchmarking)

“Tools to design the structure of software, and using the information to do analysis of components… Robot manufacturers can use this information to build complete robots and certify robots.”

5. How will RobMoSys approach help roboticists?

“PAL Robotics and other consortium partners use ROS technology, and other intelligent systems, some of this other software is not in ROS, and it needs to be integrated, using RobMoSys it’s possible to see how ROS works with other components. RobMoSys tools provide guidance.”

From a technical perspective, the benefits of the RobMoSys methodology and tools will lead to:

- >simplifying the setup and configuration of hardware and software

- easy integration and extension of software tool-chains and ecosystems in industrial production setups in a vendor-neutral style

- composable and replaceable components

- predictable and traceable properties

- reusable systems

- ease of use by simplifying the entrance and usability of software components

- reliably quality of service

- standardization of models and interfaces

- certify cablesystems

6. How do you anticipate that RobMoSys will impact on the future of European robotics? (in particular regarding end users and industrial partners)

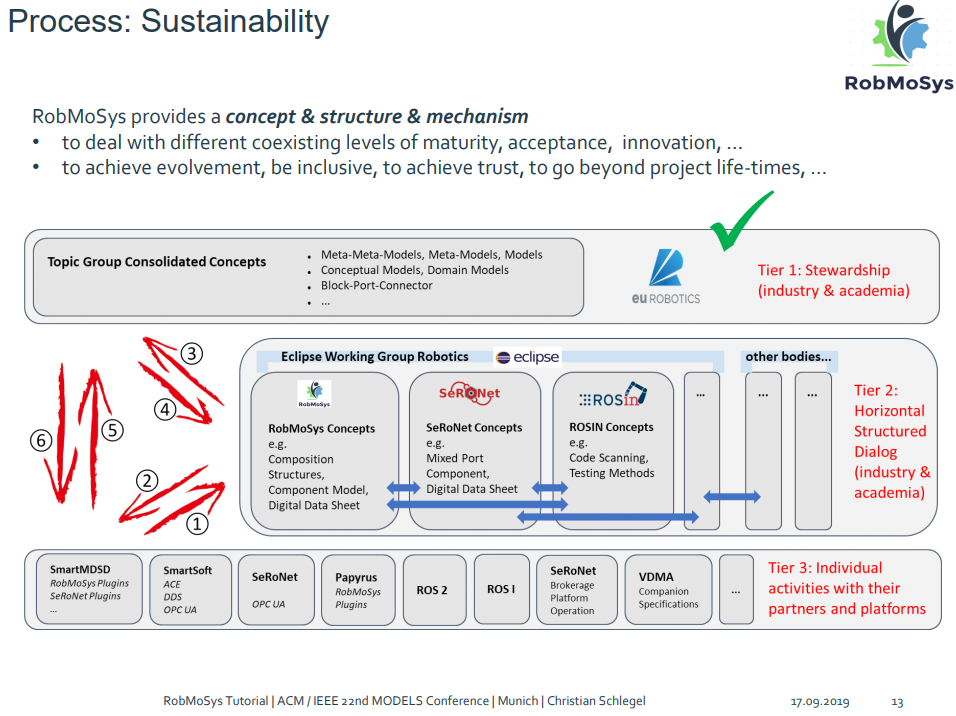

“Through improving engineering practice by developing practices, methods and tools to make the discipline more formal. The benefits include reducing costs needed to develop things, as well as being able to reuse components in different scenarios.

RobMoSys has developed a roadmap for communities – through topic groups. Topic Groups: identify gaps and challenges, describe the desired paths towards solutions, milestones to be reached at specified instants in time and with a specified quality. The first group will maintain all conceptual information, the body of knowledge behind RobMoSys. The second group is more technical – the Eclipse foundation and Eclipse tools on Eclipse technology will create a working group there to maintain the tools. This will go beyond the project.”

Find more information about the EU project RobMoSys by visiting their website. In addition to the RobMoSys project, PAL Robotics works on many other EU projects, visit our collaborative projects webpage to find out more and if you have any questions, do not hesitate to visit our contact page and reach out to us.

If you found this article informative, don’t forget to take a look at all our other articles on robotics and research projects!