Four PAL Robotics’ robots at Automatica 2018

Automatica 2018, the fair where Industry 4.0 takes shape, seems to have clear that the “Factory of the Future” involves collaborative robotics. The so-called “cobots” are based on the fact that they share the same workspace as operators – meaning, they can work safely around (and also with) people, without needing any cage or partition in between.

“Cobots” of all kinds are already assisting workers undertaking multiple tasks in production lines to optimize workflows. How are they exactly fitting in industrial processes and assembly chains?

Four robots from PAL Robotics, including “cobots” and humanoids, will be at Automatica 2018 starting tomorrow. Find them at the Service Robots Demo Park and at the stand B4.523 (in front) showing diverse roles they can have in the industry, helping in areas like intralogistics, Human-Robot collaboration, and stock-taking. Here’s a glimpse on the areas where they can assist:

1) Smart Intralogistics

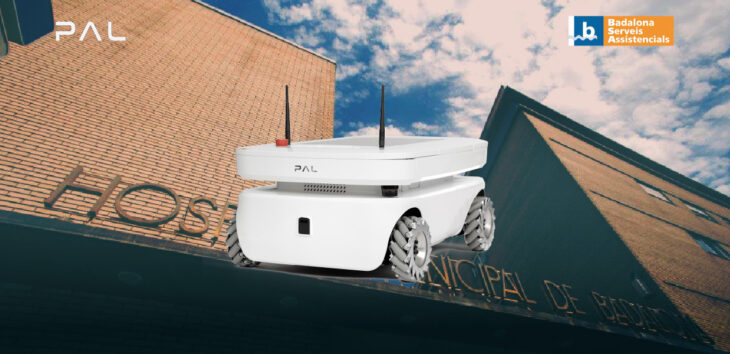

TIAGo Base with a mounted accessory that improves usability and gives a wider 3D perception.

Carrying load from one place to another can take up valuable time that could be better spent on more relevant tasks. At the end of the year, the amount of time aimed for internal deliveries is significant, and here’s where TIAGo Base comes in to deliver materials and make work easier for operators.

TIAGo Base can adapt to any specific industrial setting with customized add-ons that are easily integrated on top. A new accessory built upon TIAGo Base will be presented at Automatica, which widens its 3D perception and improves usability for autonomous intra-logistics tasks. The cobot’s smartness comes from combining an autonomous behaviour software to the existing ERP system, which helps the robot react fast when the routine is modified.

Read how TIAGo Base empowers workers at MAPCABLE.

TIAGo robot learns all the movements that the worker is teaching by simply guiding the arm, which is in gravity compensation mode.

2) Human-Robot Collaboration

TIAGo combines perception, navigation, and manipulation to provide a dynamic approach of Human-Robot collaboration in production lines. TIAGo is able to either take on autonomous assignments or assist workers.

The “cobot” is fully integrated to adapt to a diverse amount of tasks and has mounting ports for extra tools, sensors or end-effectors. From pick&place to line loading, polishing or quality inspection, TIAGo flexibly undertakes the task that best helps production.

3) Exhaustive Stocktaking

StockBot vision system enables to perform planogram checking, price checking or the analysis of products’ visibility in retail.

Whether inventory control is desired in the static environment of a warehouse or the constant unpredictability of brick and mortar, StockBot is a valuable source of updated stock data. It crafts a 3D map of everything in a given space that helps in optimizing stocktaking and inventory management.

With the latest upgrade, StockBot adds vision cameras to RFID and autonomous navigation. The outcome is fast restocking, misplacement detection and management decisions that can aid in the visibility of products and their prices. Remember how StockBot works here.

4) Looking at the Future: Research on Humanoids

REEM-C humanoid robot with a Whole-Body Control application.

The 1.65m tall bipedal platform, REEM-C, is being used in the research fields of service and collaborative robots. Active research is being conducted to improve such technologies for service and industrial tasks.

As a humanoid robot, REEM-C can walk and interact with our biped world – everything that surrounds us has been designed to fit our bipedal body. At Automatica, PAL Robotics will run a Whole-Body Control application that enables it to adapt its body and balance toward external stimuli.

RobMoSys at the Automatica Forum

We look forward to seeing you at Automatica!

If you wish to know more, take a look at PAL Robotics’ blog and don’t hesitate to get in touch with us!