Across retail stores, distribution centers, and fast-paced picking warehouses, one operational truth remains: inventory accuracy determines performance. When stock data is wrong, everything else starts to fall apart, from replenishment and order fulfillment to customer experience and revenue.

Yet maintaining accurate, up-to-date inventory information is extremely challenging in environments where thousands of items move every day.

In this context, StockBot is reshaping the way retailers work. With 12 hours of autonomy, 99% reading accuracy, and complete real-time visibility, this autonomous inventory robot provides a dependable understanding of what is in stock, where it is located, and what needs immediate attention. Rather than relying on labour-intensive, periodic counting, retailers gain an automated, continuous solution that strengthens operations end to end.

Several recurring challenges shape daily retail performance, and StockBot addresses them with consistent, reliable accuracy.

Misplaced items: Prevent lost sales before they happen

Misplaced products are among the most common sources of inventory inaccuracy. These are lost items that should be available on the shelf but have been left in the wrong aisle, placed behind other items, or positioned outside their assigned zone. The result is a lost sale, even when the product is physically present in the store.

StockBot autonomously navigates the sales floor and the backstore, scanning products and detecting these items that are not where they should be. By providing precise positional information, the robot enables the workers to correct errors quickly and restore product availability.

This translates into two significant operational benefits: shelves remain in perfect order, and retailers recover sales that would otherwise disappear unnoticed.

Stock discovery: Identifying and unlocking hidden value

While misplaced items are generally found in the wrong location, stock discovery addresses deeper visibility challenges. In high-volume retail and logistics environments, items can be stored in back rooms, left in transitional zones, or never properly registered. These lost items fall completely outside daily operations and create blind spots that inflate stock value, distort forecasting, and generate unnecessary replenishment.

Through accurate and systematic RFID scans, StockBot uncovers these products and restores full visibility over the sellable inventory. This enhanced transparency enables retailers to recover revenue, optimise replenishment strategies, and strengthen their stock data.

Phantom Inventory: Restore trust in your stock data

Phantom inventory represents one of the most costly forms of inaccuracy: systems indicate that items are in stock, yet they are not physically available. This disconnect affects revenue, planning, and customers’ ability to find the products they need.

These discrepancies typically arise from operational pressures; fast-moving stock, human error during replenishment, or items misplaced during daily activity. Regardless of the cause, the impact is substantial: retailers lose sales opportunities, forecasting becomes unreliable, and replenishment processes begin to lose alignment with actual demand.

StockBot resolves this issue by conducting accurate, autonomous RFID scans that ensure stock levels reflect reality at all times. With its high reading accuracy and consistent coverage across the store or warehouse, the robot detects mismatches early, allowing workers to correct them before they lead to further errors.

Virtual shielding: Avoid costly physical modifications

Many retailers rely on physical shielding materials to prevent cross-readings between adjacent areas such as the sales floor and the stockroom. This approach is not only expensive; it also requires installation work, limits store layout flexibility, and must be maintained over time.

StockBot removes this dependency through virtual shielding. By scanning only the intended areas and avoiding unwanted cross-reads, the robot delivers accurate, targeted data without any additional materials or structural adjustments.

The result is a simpler, more adaptable operation with lower costs and consistently higher accuracy.

Picking warehouses: Reliable accuracy in complex environments

Picking warehouses move at high speed, and even small location errors can disrupt the entire fulfillment flow. Traditional counting methods offer only partial visibility, while RFID infrastructures often face challenges such as signal interference from metal structures and high tag density.

These factors can lead to discrepancies that slow down picking and increase rework. StockBot overcomes these obstacles and maintains accuracy even in demanding warehouse layouts. By continuously validating product locations, the robot reduces errors and supports smoother, more efficient picking operations.

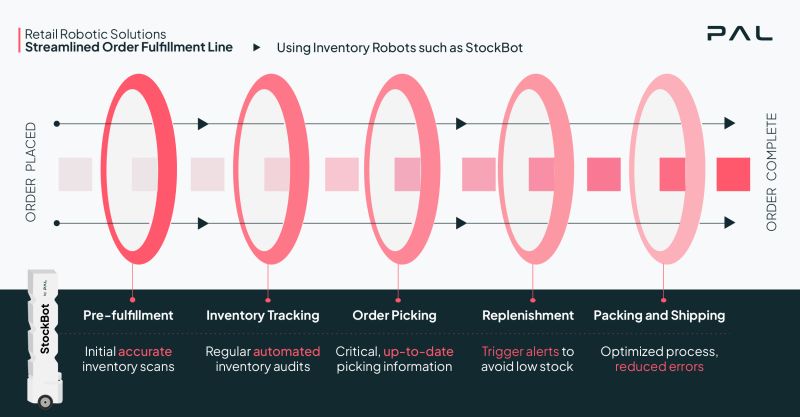

From shelf to shipment: strengthen every step of fulfillment

Inventory accuracy directly shapes how efficiently retailers execute every stage of the fulfillment process. When stock data is reliable, operations such as replenishment, picking, restocking, and shipping become faster, more predictable, and less error-prone. StockBot enables this by providing continuous, autonomous inventory visibility that strengthens decision-making from shelf to shipment.

The visual below shows how StockBot supports each step of the fulfillment chain:

Retailers using StockBot report measurable improvements across key operational metrics:

- 50% faster picking

- 30% shorter fulfillment time

- 60% reduction in scanning time

These gains translate into smoother processes and a more resilient supply chain, one where teams can focus on high-value tasks instead of tracking down inconsistencies.

A transformative tool for modern retail

In essence, StockBot does more than automate inventory counts, it creates a stable, trustworthy information backbone that enables retailers to operate with greater speed, clarity, and confidence. Inventory accuracy, far from being just a metric, is becoming a strategic advantage. By automating stock control, detecting errors early, and maintaining real-time visibility, solutions like StockBot empower retailers to reduce losses, maximise sales, and optimise operational costs.

This year, we will be at NRF 2026, where we will showcase our retail automation solution and exchange insights with industry professionals shaping the future of the sector. We welcome you to meet us there and discover how autonomous inventory management can transform retail operations end to end.