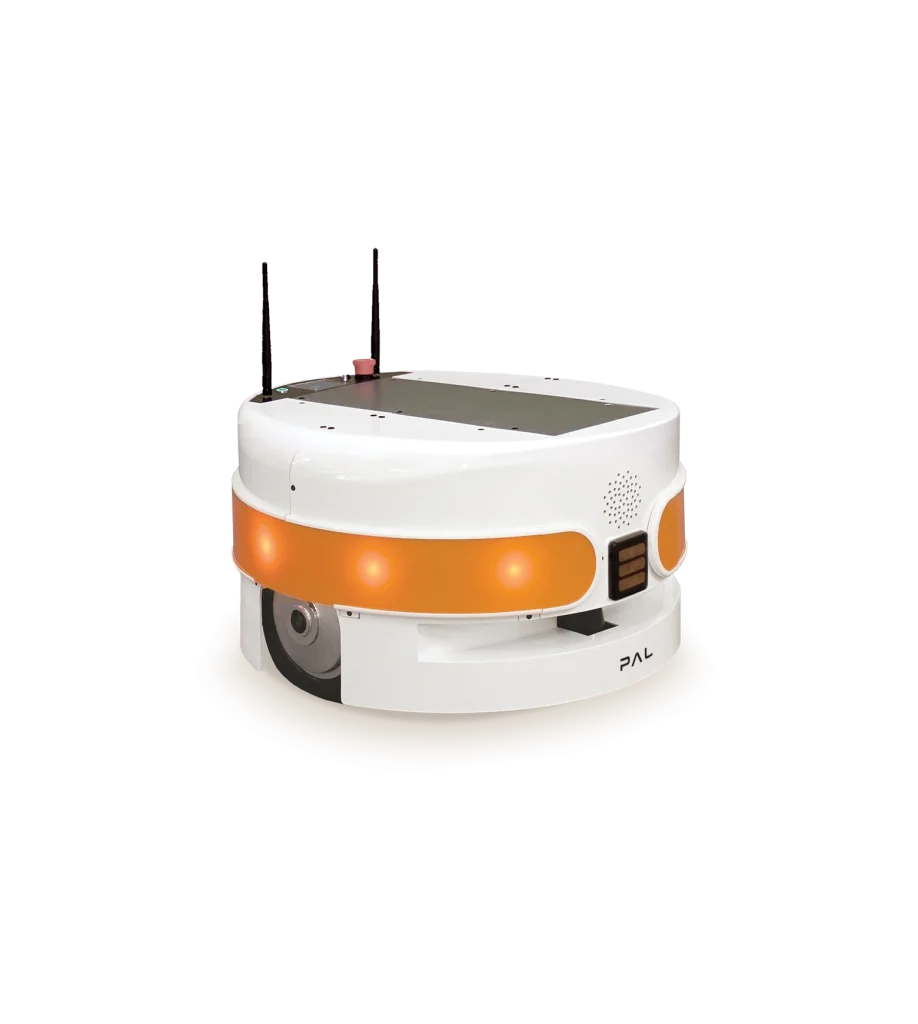

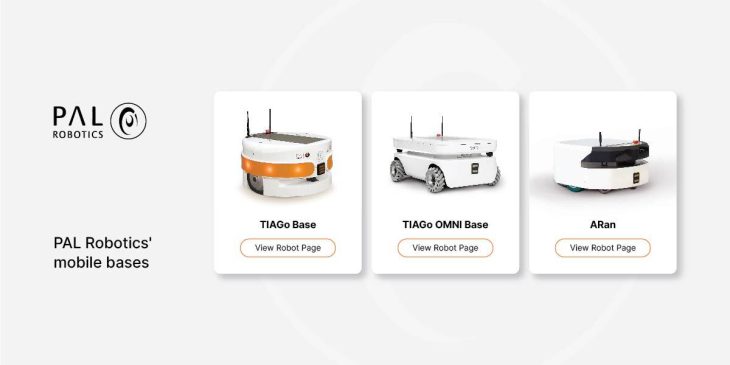

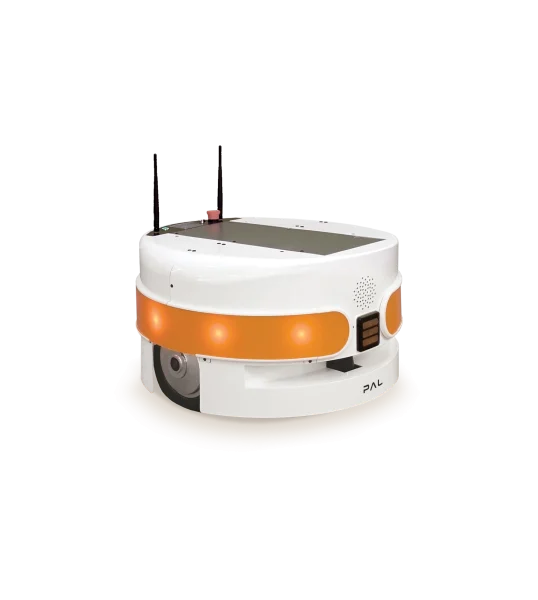

TIAGO BASE

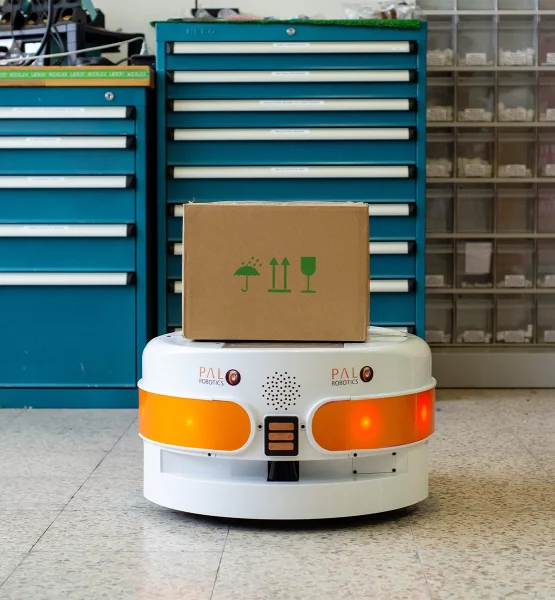

Redefining indoor logistics

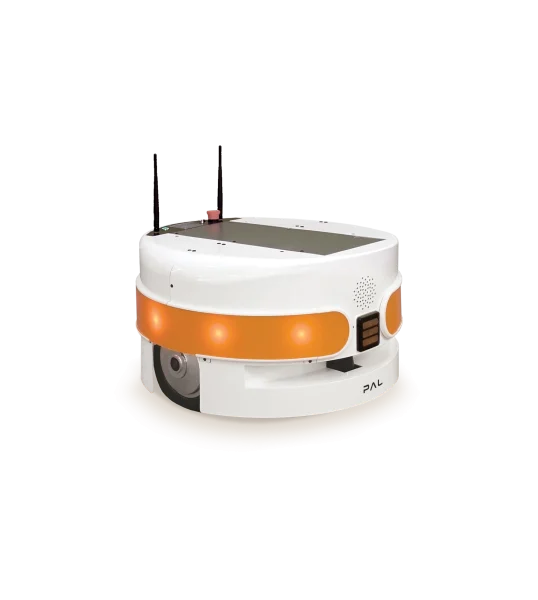

TIAGo Base is our modular and flexible autonomous mobile robot to automate your deliveries and empower your research with advanced navigation capabilities. Designed for the maximum versatility, TIAGo Base is fully customisable.

Focused on productivity

Maximised output with more efficient operations and higher value tasks

Cost-effective and scalable

Streamlines operations to reduce costs and scale with business needs

Flexible & Adaptable

Adapts swiftly to whatever layout and task

User-friendly

Easy to use and tailored for your specific business and research

Technical

Specifications

| Payload | 70 kg |

|---|---|

| Max speed | 1 m/s |

| Compactness | ∅ 540 mm |

| Dimensions | 54 x 30 cm |

| Weight | 47 kg |

| Max autonomy | 10 h |

| Wheels | 2x motorised and 4x caster |

| Computer | Intel i5 with 256 GB SSD |

OPEN SOURCE

TIAGo Base simulation model and tutorials available at: wiki.ros.org/Robots/TIAGo-base/

PREMIUM

Software

Watch

TIAGo Base in action

ADD-ONS

Accessories

TIAGo Base

News

TIAGo Base

Frequently Asked Questions

Explore our FAQ section for insights on TIAGo Base, covering everything from setup and operation to maintenance and troubleshooting tips.